There's a approach that is certainly useful for recalibrating a Resource and it is recognized as bench calibration. It is an important method that must be carried out to be able to make sure that every one of the elements of a tool are performing properly. If a Instrument just isn't effectively re calibrated, it can lead to inaccurate measurement. This may end up in a number of issues.

Basic method

There are numerous techniques linked to the whole process of recalibrating a Software. Calibration includes comparing an instrument's output using a reference instrument's. This comparison makes it possible for the measuring instrument to generate extra exact effects.

The most simple process is to use a list of Accredited gages blocks. These usually are produced to national specifications. Usually, they have got a thickness of 1 mm as well as a diameter of 63 mm.

Applying these gages, you must evaluate a range of masses. Usually, you should have five to 10 check factors. By way of example, you could possibly measure displacement, inner tension, and corner radius.

Throughout calibration, you will need to record The end result that may help you figure out how to proceed next. You can also benefit from automatic workflows to retrieve and evaluate data.

To achieve this, you need a https://www.emlcalibration.com good calibration program. A well-composed system will demonstrate the methods involved with the calibration course of action. It will incorporate the functionality technical specs you'll use, the solutions and resources used, and The explanations to the calibration.

Accreditation

Should you be Performing to create high-quality merchandise, You'll have to calibrate your instruments. This method is necessary to make sure the accuracy of the products and procedures. You should use a Accredited calibration services supplier to fulfill your specifications.

Accredited laboratories verify their complex and screening competence. Accreditation also gives assurance the lab continues to be independently confirmed by a third party.

The scope of accreditation defines the parts of the laboratory and the types of measurements it's effective at carrying out. Furthermore, it describes the type of apparatus which is utilised. An accrediting entire body will commonly assess the caliber of a lab's surroundings and staff.

The calibration laboratory is expected to comply with a rigid list of demands. These incorporate the security of your personnel along with the setting. A risk management method can also be necessary.

ISO/IEC/EN 17025 is a global common for excellent. It requires a possibility administration system and an intensive audit in the lab. On top of that, the calibration laboratory is required to acquire an excellent assurance program.

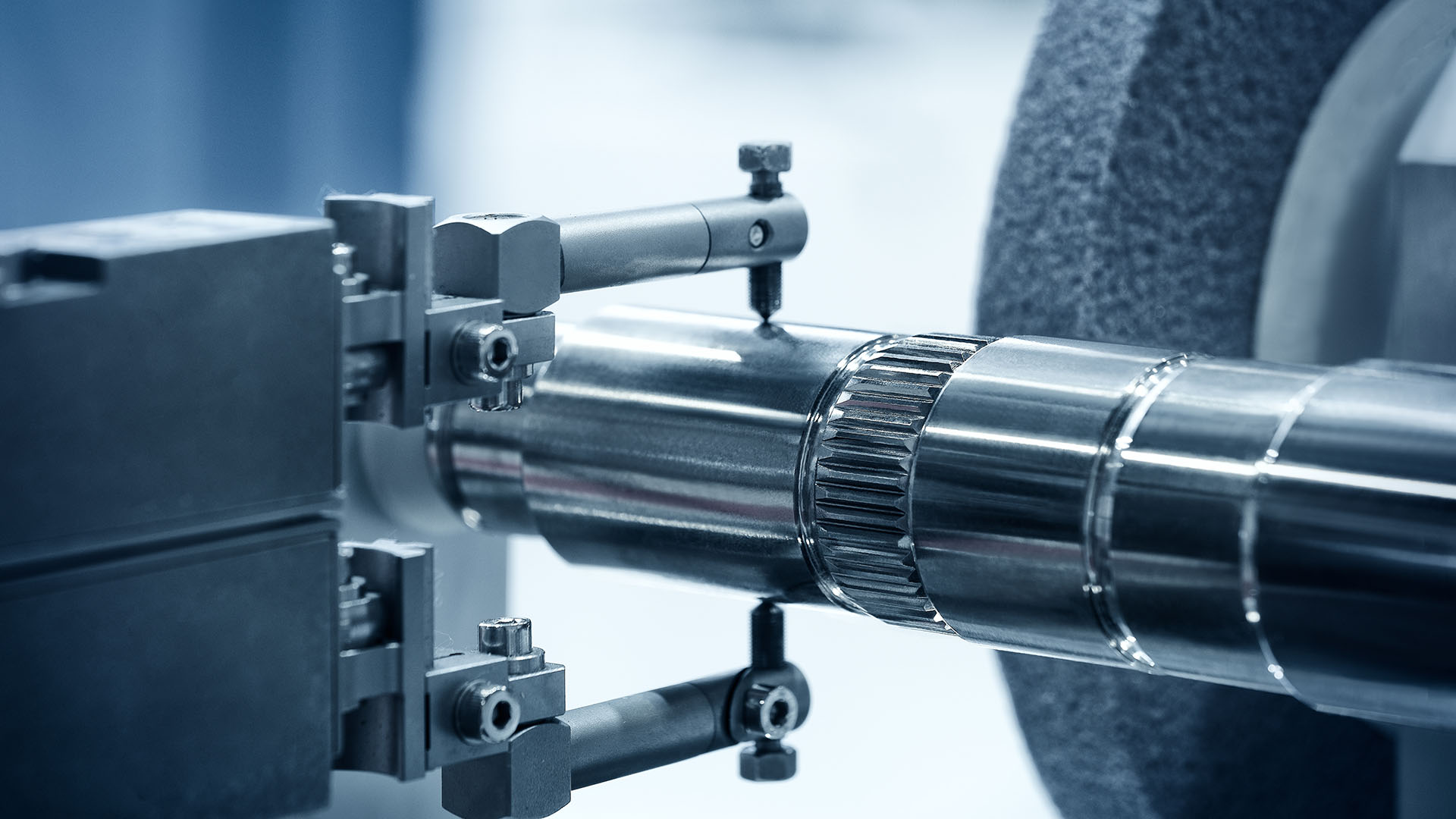

Bench calibration

If your bench calibration Device needs to be recalibrated, it is crucial to understand how to thoroughly conduct the procedure. This can ensure that the measurement is traceable for the Nationwide Institute of Specifications https://en.search.wordpress.com/?src=organic&q=calibration and Know-how (NIST) standard.

Calibration is the first step to protecting the overall performance of one's measurement equipment. It is additionally the one way to ensure the accuracy within your products.

Bench calibration requires disconnecting your instrument from the process it really is measuring, cleansing it, then mounting it on a exam stand. To become powerful, the process need to be performed in a controlled setting.

A controlled environment helps you to decrease the complete uncertainty and the risk of problems. The bench must have access to a tension resource. Typically, this is the hand pump. Furthermore, the gauge needs to be mounted in the exact same orientation as the procedure.

So as to effectively calibrate your bench scale, You will need a reference force gauge that may be traced again into a producer. Normally, you are able to expect the traceable tension reference to get an accuracy of four situations the accuracy of one's system.

Traceability

Traceability is the process of connecting the final results of the calibration for the founded expectations. This can be a way to attenuate possibility linked to measurement equipment as well as instruments used to measure.

The Countrywide Institute of Expectations and Know-how (NIST) has long been creating specialized information on traceability. NIST also offers certifications for reference products and measurement protocols. In addition it conducts coordinated outreach plans on traceability.

The NIST Top quality Process for Measurement Companies defines traceability as being the link among the measurements and results of the calibration plus the established standards. Whether the measurements are to get traced to NIST or to a different conventional, the Corporation will have to abide by check processes and protocol.

Traceability is usually a prerequisite to Conference the requirements of globally regulatory companies. A good merchandise can be useless if it has no assurance of correct measurement. Also, it could lead to heavy charges if it fails.

The first step in traceability is to determine a series of reference. Utilizing the Global Method of Models, or SI, a tool needs to be calibrated and its benefits are then verified and recognized.